Within their design criteria, Taber pressure transducers can be configured to measure pressure with respect to all the common pressure references.

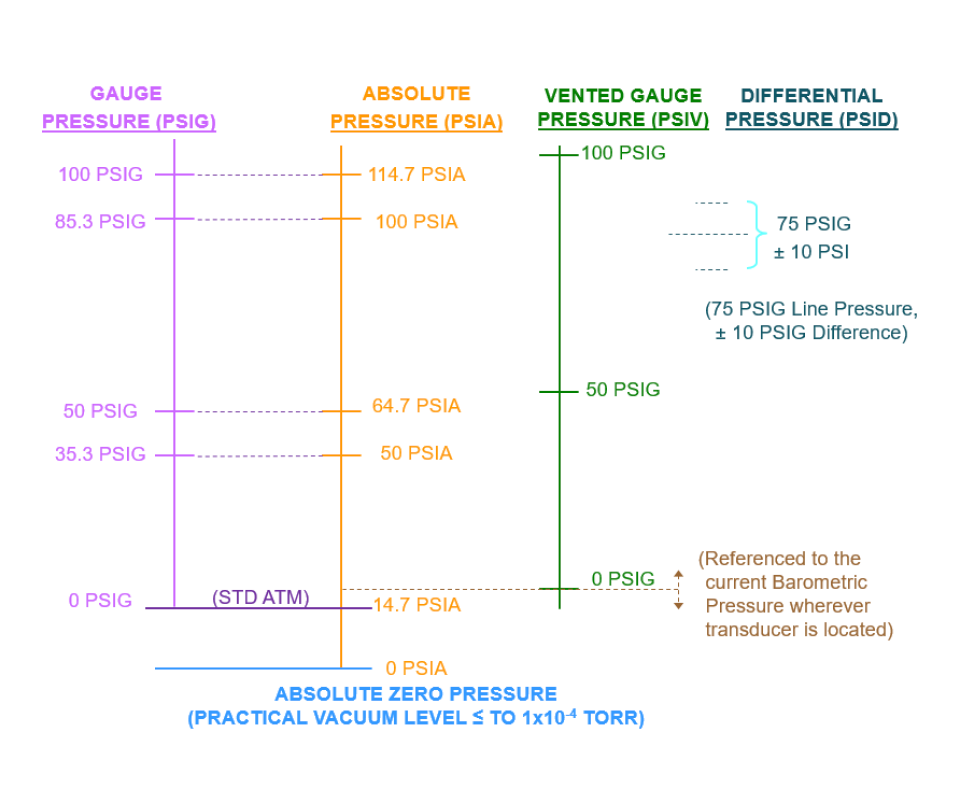

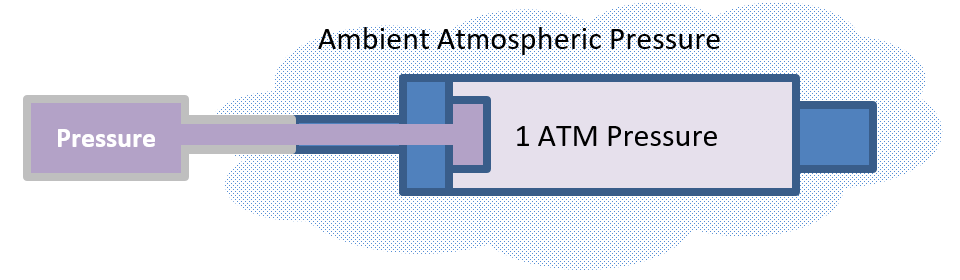

PSIG is nominally measured relative to ambient pressure. For modern hermetically sealed pressure transducers, gauge pressure is usually measured relative to a reference cavity within the transducer body. Above 100 PSI [6.9 bar], this cavity is typically the electronics compartment that may or may not be evacuated. For ranges of 100 PSI and below, a separate vacuum compartment is used as a zero pressure reference and the signal output is electronically offset by 1 atmosphere (atm). Common measurement units are pressure per square inch gauge (PSIG) or bar gauge (bar or bar/g).

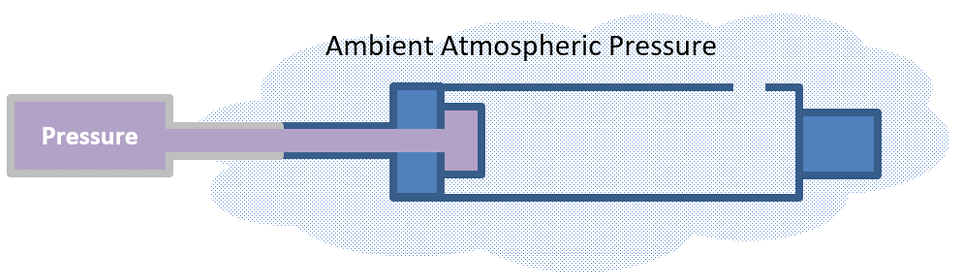

PSIV is measured with reference to true ambient atmospheric pressure. One side of the diaphragm is exposed to fluid pressure, while the other side is exposed to ambient air pressure. Because actual ambient air pressure is allowed inside behind the sensing element via a screened or vented hole in the body, the strain gauges or electronic components could be exposed to atmospheric contamination or condensation. For pressure ranges below 50 PSI, ambient back pressure could damage the sensing mechanism. Common measurement units would be pressure per square inch vented (PSIV), or Bar vented (Bar, or BarV).

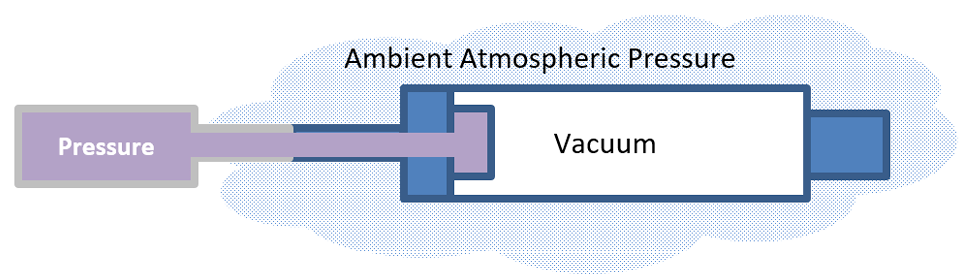

PSIA is measured relative to full vacuum. One side of the diaphragm is exposed to the fluid pressure while the other side is exposed to an evacuated chamber. Common measurement units are pressure per square inch absolute (PSIA) or bar absolute (Bar-A).

PSID is the difference in static pressure as measured between two points at the same elevation located in two different locations within the system. Common measurement units are pressure per square inch differential (PSID) or bar differential (Bar-D). Differential pressures are usually considered to be unidirectional and an example of how the pressure range is written would be 0-50 PSID. Unidirectional differential pressure can also be expressed as pressure per square inch unidirectional, e.g. 50 PSIU or 50 PSIUD.

Sometimes a differential pressure scale is bi-directional, i.e. balanced over zero. In this case, it is expressed as pressure per square inch bidirectional (PSIB or PSIBD). Written examples of these pressure ranges are ± 25 PSID, 25 PSIBD (PSI bi-directional), or -25 to 0 to +25 PSID.

It is common to use a differential pressure transducer to measure the level of fluid in a container (fluid level measurement). In this case, one port of the transducer is tapped into the bottom of the container, while the other port is left open to ambient air pressure. A simple chart can convert the fluid column pressure at the bottom of the container to a corresponding surface height, or level.

In some special applications, differential pressure transducers with high overload pressure capabilities are used as PSIV (True Gauge) transducers. Their ability to accommodate high line pressure and high overload (proof) pressure gives them the power to accurately measure very small pressure differences between ambient pressure on the one side, yet support high static line pressures, or bursts of system pressure on the other side.

If you have a question regarding Taber Transducer products, please complete the following form and we will contact you as soon as possible.

US & Canada