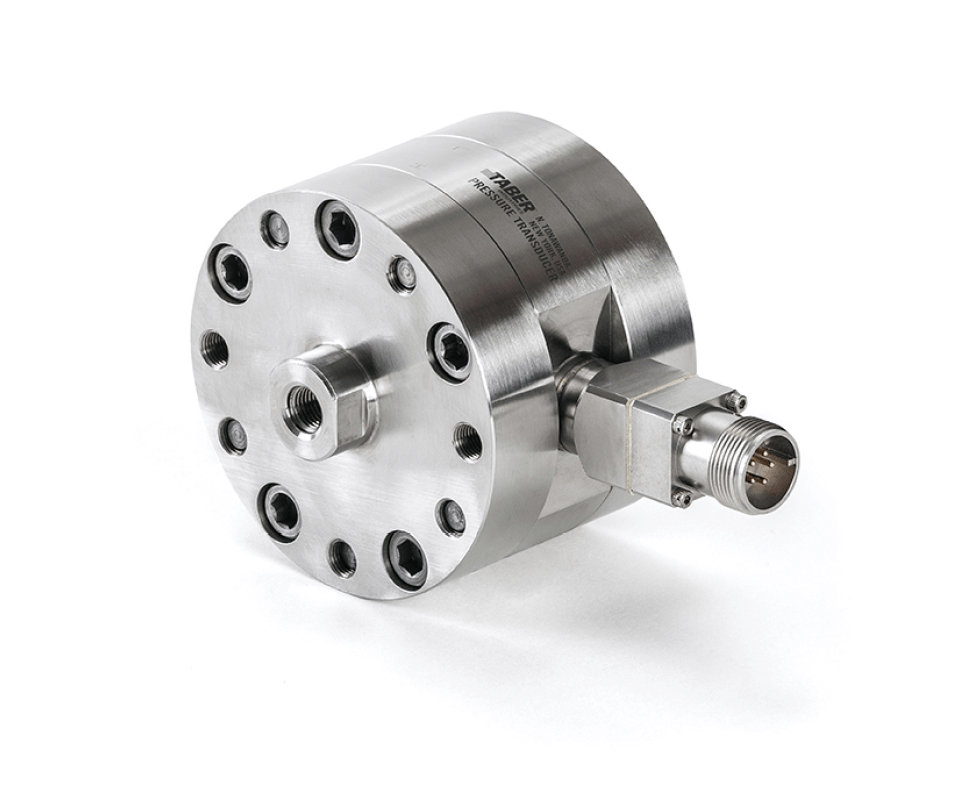

Taber Industries prides itself on its engineering capabilities and its ability to configure transducers outside the realm of standard specifications. Taber is happy to work with its customers to provide what is needed for any application. See below for a number of services Taber’s engineering and sales departments can provide.

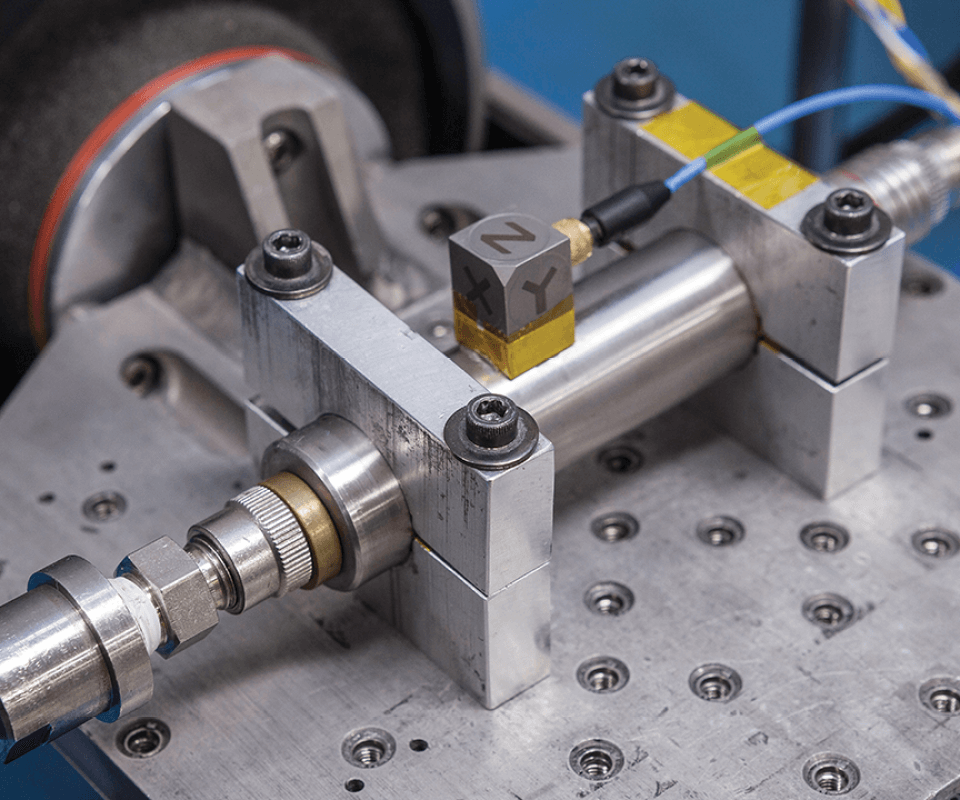

Taber has numerous in-house and 3rd party testing capabilities that have been performed for a wide range of customer programs.

• Environmental

• Shock/Vibration

• EMI/EMC

• Radiographic &/or Dye Penetrant Inspection

• Pressure Cycling

• Thermal Cycling

• Thermal Vacuum Testing

• Precision Cleaning

• Oxygen Cleaning

• Etc.

Taber’s project engineering team is ready to provide individualized customer service for any type of program. From military to space programs, Taber has great experience in delivering quality products that meet our customer’s requirements in order to fulfill even the most extreme program demands.

All Taber transducers are custom-built according to customer specifications. This offers the flexibility required to meet detailed customer requirements and potentially replace heritage designs of other transducer vendors. Different transducer configurations are available for the following option types:

• Pigtail Cables/Wiring

• Secondary Containment

• Materials

• Non-standard pressure ports and receptacles

• Special Packaging and MIL-STD Packaging

• Mounting configurations, including custom mounting feet

Taber is willing to engage with our customers where we can work collaboratively to find new ways to meet customer requirements while also creating standards that can be used for broader markets.

Taber has supported numerous customer program initiatives. Therefore, we have extensive experience crafting SDRL/CDRL documents that meet all relevant industry expectations. The types of documents Taber has provided are:

• Qualification by Similarity Documentation

• Mechanical Structural Analysis Documentation

• Electrical Stress Analysis Documentation

• Radiation Analysis Documentation

• FMEA/FMECA Documentation

• Test Procedure Documentation

• Configuration Management and other Program Documentation

• Materials and Process List Documentation

• User Manuals

• Weld Qualification Documentation

Since Taber transducers are custom-made, building prototype transducers for preliminary customer use and testing is well within our capabilities. Taber project engineers will work with your team to provide prototypes that meet general requirements demonstrating design effectiveness while also enabling the subsequent production of flight-type transducers for full use.

If you have a question regarding Taber Transducer products, please complete the following form and we will contact you as soon as possible.

US & Canada